As the cement industry faces the dual challenge of meeting growing demand while reducing its environmental footprint, Cementir strategy focusses on reducing carbon emissions, advancing low-carbon technologies and fostering sustainable growth.

While tackling process emissions through the use of alternative fuels and raw materials and cutting-edge carbon capture and storage technology, Cementir continues to drive innovation in low-carbon products and technologies to address the carbon footprint of cement. The company has developed Futurecem® and D-Carb®, providing the grey and white cement markets with lower-carbon alternatives to traditional Portland cements.

Leveraging limestone and calcined clay technology

Futurecem is the result of extensive applied research, developed in recent years at the Cementir Group Research and Quality Centre located in Aalborg, Denmark. It covers the entire value chain, from raw material assessment and manufacturing technology to concrete technology.

This low-carbon grey cement is based on a synergy between limestone and calcined clay that allows clinker replacement in cement. The combination of materials has resulted in a more sustainable and better-performing cement with up to 30 per cent lower carbon footprint compared with ordinary Portland cement. The low-carbon benefits are also achieved while preserving strength and quality.

Futurecem has been available on the market in Denmark since January 2021, establishing the Cementir Group as the market leader in sustainable and low-carbon cement, based on limestone-calcined clay technology. Primarily targeted at the ready-mix concrete (RMC) segment, customers use its special properties to make concrete more stable against variations in consistency and easier to pump, which is usually a challenge with the rather cement-poor concrete used in Denmark. The growth in the RMC segment has continued in 2024 and 2025 in terms of both number of customers using it and market share.

Along with RMC, a growing number of Danish concrete precast producers are implementing Futurecem in their production through a complete testing programme on site. The main difference perceived is the light-brown colour of the concrete, which is considered as a seal of quality and visible proof for builders to demonstrate the sustainable nature of their building.

Beyond Denmark

Production of this lower-carbon cement has taken place since 2023 at CCB, the Cementir Group’s subsidiary in Belgium, and was fully commercialised in the reference markets (France and Belgium) after gaining the ATG (Agrément Technique) certification that allows its use in concrete according to Belgian standards. The ATG was required as an additional certification due to CCB’s status as a pioneer of limestone-calcined clay cement in Belgium.

Thanks to this development, CCB has been able to exploit new applications as well as tackling the RMC market in the most relevant exposure classes. In collaboration with customers, Futurecem is now a reference to be further implemented in precast elements: the precast sector is in fact a leading consumer of this type of cement. Internally in CCB Béton, Futurecem implementation has been ongoing.

2025 developments

Most significant is development within concrete products in 2025. By implementing Futurecem in double-layer concrete used in the production of tiles and paving stones, producers have succeeded in considerably lowering the carbon footprint, and at the same time, maintaining the high quality and properties of the products. This has meant an almost explosive spike in its application within this segment in 2025.

Futurecem has also gained greater traction in the retail segment, where several DIY chains have put the product on their shelves over the past year because their professional customers demand cement with a lower CO2 footprint.

Case studies

In 2025, Futurecem was used for the production of all the concrete for one of the largest 3D-printed buildings in the world, The Forest Track in Holstebro, Denmark. The project consists of 36 student housing units, representing a total surface area of 1654m2.

The RMC and concrete elements for the ambitious sustainable building UN17 Village in Ørestad, Copenhagen, were also manufactured using Futurecem. The project, with more than 500 apartments, was completed in 2024 and is known as the world’s first housing project integrating all 17 UN Global Goals in the same building.

In addition, a total of 4880m3 Futurecem-based RMC was used in the Bjarke Ingels Group head office, which opened in 2023 and was awarded the DGNB Gold certificate. The use of UNI-Green (now UNI-Versal) – a new type of Futurecem-based concrete from Cementir’s subsidiary Unicon – has resulted in ~25 per cent CO2 reduction in the carbon footprint of concrete.

Furthermore, in 2024, Unicon Denmark demonstrated a solid performance and steadfast commitment to sustainability by launching the UNI-PLUS series, setting a pioneering standard for the industry. The series, based on Futurecem, significantly reduces CO2 emissions by up to 50 per cent, through its integration and additional initiatives.

Unicon also takes full advantage of the fact that Futurecem is documented through an up-to-date Environmental Product Declaration (EPD), ensuring that Unicon’s own RMC EPDs remain best-in-class and provide the market with essential documentation credentials.

The UN17 Village in Ørestad, Copenhagen, Denmark, is the first housing project to integrate all 17 UN Global Goals in the same building and uses Futurecem in its ready-mix concrete and concrete elements.

Decarbonisation of white cement

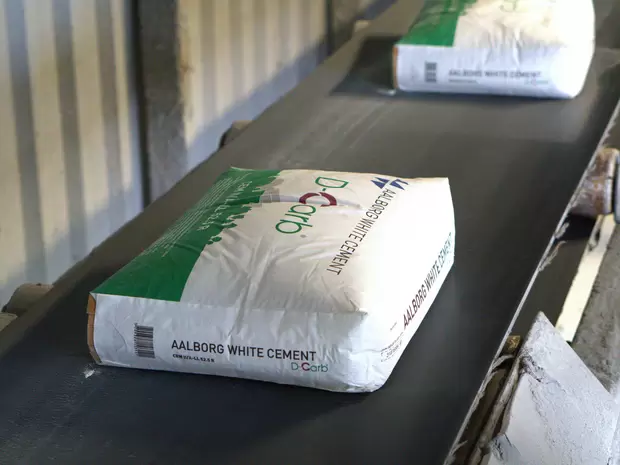

Cementir’s commitment to sustainability extends to its white cement production with the launch of D-Carb. Transitioning towards more sustainable production in the white cement segment is more challenging than grey cement, due to major differences in the production process as well as the need to guarantee colorimetric performance. Common actions to reduce the carbon footprint of grey cement production are not suitable for white cement production.

D-Carb is a new umbrella brand for white low-carbon cements, supporting the Cementir Group’s white cement decarbonisation efforts. The D-Carb range was first launched in European markets in 2024, with II/ALL 52.5R cement. Its carbon footprint is 15 per cent lower compared to Aalborg White® CEM I, while maintaining the same high short-term performance. Its sustainability credentials are validated by third-party EPDs.

Thanks to in-house extended expertise in white cement production technology, the synergy between the well-known Aalborg White clinker and limestone has been optimised by choosing a fit-for-purpose grinding aid to achieve an outstanding performance at early ages comparable to Aalborg White CEM I. Leveraging the limestone fineness as well as the overall particle size distribution, D-Carb allows an enhanced and consistent rheology considered to be a seal of quality in wet-cast applications that mainly use self-compacting concrete. These superior rheological properties enable customers to achieve a finish that resembles a marble surface. This development followed years of R&D and extensive industrial-scale trials.

Since its launch, D-Carb® has quickly gained broad recognition and adoption across multiple industries. Customers experienced a smooth transition from CEM I to D-Carb as it integrates well with their production processes without requiring major formulation changes. Even high performances can be achieved with a specific fine-tuning.

Project use

D-Carb is now officially used in two projects by C-concrete, part of the Cordeel Group. The first is the new 380 kV GIS high-voltage substation in Amaliahaven, The Netherlands, for TenneT, where white precast sandwich panels made with D-Carb are being employed. The project is expected to be completed in early 2026.

The second is the AZ Jan Portaels Hospital in Vilvoorde, Belgium, designed as a hospital of the future, where D-Carb was used to produce precast facade frames. With high whiteness and outstanding strength performance, D-Carb delivers both structural durability and visual elegance in this engineering and build project.

A third project in which D-Carb has been used is the Aquamarijn Residence project in De Panne, Belgium, by Enjoy Concrete. Aquamarijn is a striking 11-storey coastal development. The precast concrete parapets of the building were made with D-Carb lower-carbon white cement, with varying heights between the lower and upper floors. On the lower floors, the parapets are taller to block the view from the surrounding streets, ensuring greater privacy for the interior spaces. The project required high-quality, high-performance white cement to produce self-compacting concrete suitable for the parapet elements.

Following Cementir Group’s decarbonisation strategy, this year D-Carb family has been expanded into the Asia-Pacific region, bringing the group one step closer to its commitment of achieving net zero emissions by 2050. It also strengthens its support for the building and construction sectors in meeting key decarbonisation targets.

D-Carb was used in the production of white precast sandwich panels for the new high-voltage substation in Amaliahaven, The Netherlands

Lower-carbon solutions range

To support the transition, Cementir Group also produces blended cements by leveraging the main SCMs, such as fly ash, granulated blastfurnace slag and pozzolan, to offer low-carbon solutions to customers as well as to strive towards its CO2 emission reduction target.

Cementir’s lower-carbon products are a vital and forward-looking contribution to the green transformation of the construction sector, where cement and concrete remain indispensable building materials. Nonetheless, the company’s product design and development efforts continue every day in collaboration with customers to ensure market viability.

Attachments

Empowering the lower-carbon transition in grey and white_ICR Nov. Issue

Share on