Cementir Group is guided by innovation, glocalisation and sustainability to achieve a sustainable transition in white cement. This has resulted in the formulation of a lowcarbon white cement range with a performance comparable to traditional white cements.

International Cement Review | January 2026

Three key strategic pillars

The group is guided by three core strategic pillars: innovation, “glocalisation” and sustainability in white cement. Cementir Group’s leadership in the white cement industry is anchored in its global presence, innovation-driven strategy, glocal adaptation and robust commitment to sustainability. By focussing on advanced technologies and responsible practices, Cementir is at the forefront of delivering sustainable and high performing building materials for the future of construction.

Specifically, “global localisation” (or “glocalisation”) is central to Cementir’s strategy in white cement. By combining global knowledge with local adaptation, the group delivers tailored solutions that meet the specific needs of diverse markets. Cementir’s diversified customer base and production footprint enable it to support client growth through customised services, know-how sharing, and strategic partnerships. As Michele Di Marino, Cementir Group’s chief sales, marketing and commercial development officer, explains, “Our ambition is to unlock the full potential of working with customers by having a new strategic focus towards product- and technology-based applications. By enhancing visibility into the customer’s value chain, we aim to provide a differentiated, tailored and sustainable value proposition which starts from the product offering, developing into value-added services, co-development, and innovation initiatives.”

As part of its sustainable transition in white cement, Cementir Group provides its global expertise to find the best local white cement solutions | Photo credits:C-concrete

Being global means sharing knowledge and resources, but acting local means listening, adapting and co-creating with partners on the ground. It is about understanding the specific challenges and opportunities in each market and responding with solutions that make a real difference. Cementir’s glocal strategy enables resilience and agility, allowing the company to adapt to changing market conditions and regulatory shifts. Innovations developed at the global level, such as D-Carb® for white cement, can be rapidly deployed and customised for local markets, accelerating the adoption of sustainable construction materials worldwide. “Our strength lies in our ability to combine global innovation with local expertise, ensuring that every solution is relevant and impactful for the communities we serve,” says Mr Di Marino.

Sustainability is a foundational pillar of Cementir Group’s strategy. The company is committed to achieving netzero emissions by 2050 and is actively investing in decarbonisation projects such as futurecem® and D-Carb®. Cementir’s sustainability strategy focusses on reducing carbon emissions, advancing low-carbon technologies and fostering sustainable growth. Key initiatives include alternative fuels, district heating in Denmark, green quarry projects in China, and the development of lower-carbon products such as D-Carb white cement.

D-Carb: from R&D to industrial validation

The journey towards decarbonising white cement production is uniquely challenging. Unlike grey cement, white cement demands strict colorimetric performance and purity, limiting the use of common decarbonisation strategies such as alternative fuels and supplementary cementitious materials. Cementir Group recognised these constraints and embarked on a comprehensive innovation programme to address them.

“The D-Carb range emerged from this context – a family of lower-carbon white cements designed to deliver both sustainability and performance. The development process was deeply collaborative, involving technical partnerships with admixture companies and close engagement with key customers right the design phase. Fast prototyping and extensive laboratory- and industrialscale trials were central to the approach, ensuring that the new formulations would meet the demanding requirements of both colour and mechanical performance,” says Stefano Zampaletta, group product and solution manager.

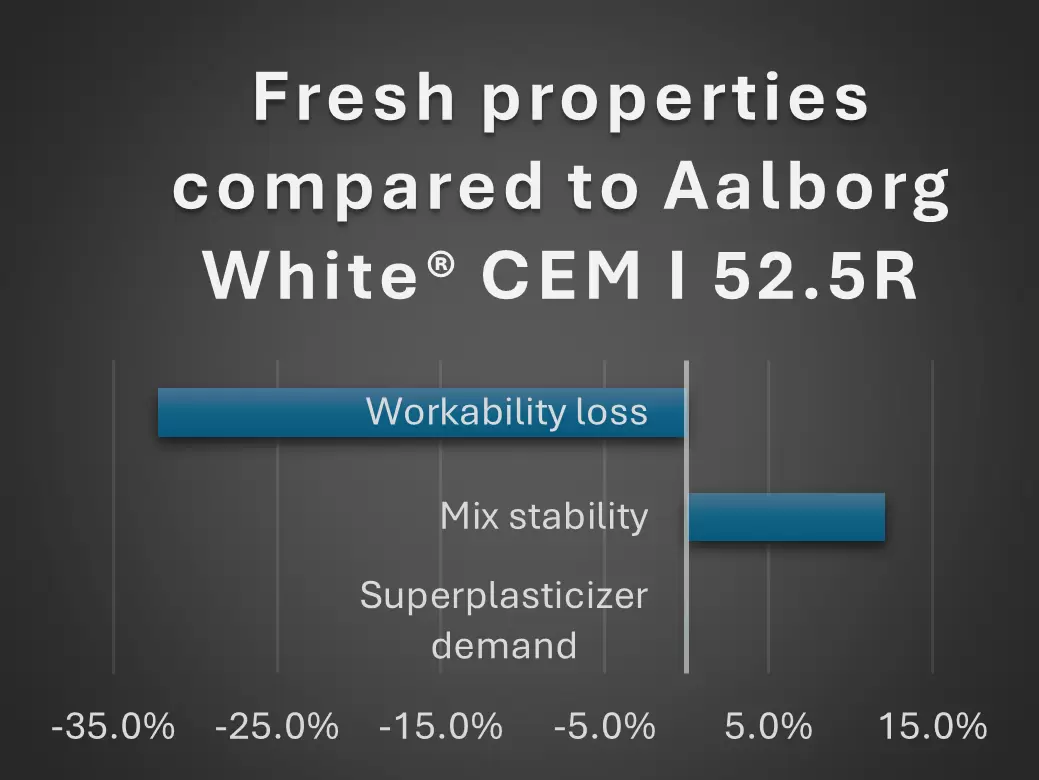

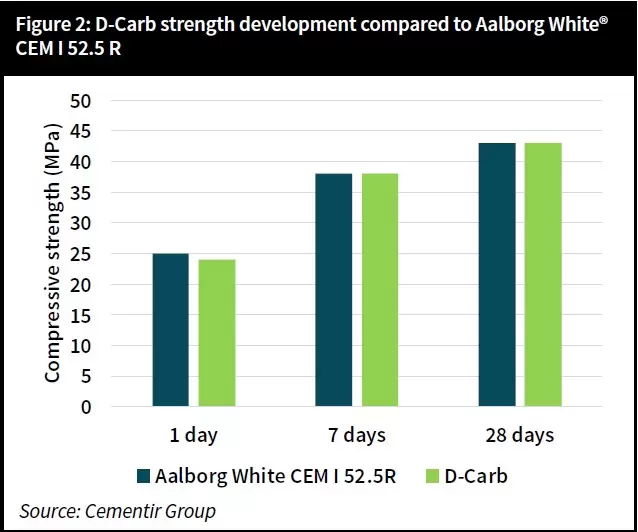

A crucial milestone was the launch of D-Carb CEM II/A-LL 52.5R, first produced at the Aalborg Portland plant in Denmark. This product achieves a 15 per cent reduction in CO emissions compared with the benchmark Aalborg White CEM I 52.5R, as validated by third-party environmental product declarations (EPDs). The innovation lies in the optimised synergy between Aalborg White clinker and high-purity limestone, supported by a fit-forpurpose grinding aid. This combination delivers outstanding early-age strength and enhanced rheology, crucial for applications such as self-compacting concrete and wet-cast elements, where a marble-like finish is desired.

Industrial partners played a pivotal role in validating D-Carb’s performance. For example, C-concrete, a major precast producer in the Benelux region, conducted a comprehensive laboratory testing programme. The results confirmed that D-Carb could seamlessly replace Aalborg White CEM I in existing formulations, achieving the required 28-day compressive strength without major adjustments. This smooth transition was echoed by Enjoy Concrete, which successfully used D-Carb in the Aquamarijn Residence project, highlighting its comparable strength, excellent workability, and 15 per cent lower footprint.

Figure 1: D-Carb fresh properties compared to Aalborg White® CEM I 52.5 R

Figure 2: D-Carb strength development compared to Aalborg White® CEM I 52.5 R

Global expansion and market adoption

Following successful initial testing, Cementir Group started a phased roll-out of the D-Carb range, first targeting the European market and then expanding globally. The launch strategy was closely aligned with the company’s broader decarbonisation road map, which includes ambitious CO reduction targets validated by the Science, Based Targets initiative and ongoing investments in disruptive technologies such as carbon capture and storage.

In 2024 D-Carb was introduced across Europe, quickly gaining recognition and adoption in multiple industries. The product’s ability to deliver high early strength, consistent whiteness and superior rheology made it particularly attractive for precast and architectural concrete applications. The range was soon expanded to the Asia-Pacific region, with Aalborg Portland Malaysia launching D-Carb CEM II/A-LL 52.5N, offering a 12 per cent reduction in CO emissions and targeting markets initially in Australia. This expansion was driven by rising demand for sustainable construction materials, clear policy direction and defined industrial decarbonisation targets in the region.

More recently, two D-Carb variants were launched in the Middle East and Africa (MEA) , produced at Sinai White Cement Co in Egypt. These products – CEM II/A-LL 52.5N and CEM II/B-LL 42.5N – feature around 10 and 20 per cent emission reduction, respectively, compared to Aalborg White CEM I 52.5R. The dual-product launch supports industrial end users in MEA in meeting emerging lower-carbon requirements without compromising on performance or aesthetics.

Cementir’s strategic geographic presence and technical support infrastructure have been key enablers of this global roll-out, ensuring that customers in diverse markets can transition smoothly to lower-carbon solutions. This is coherent with Cementir Group’s “ glocal” approach, strategising global and acting local.

Voice of customers

As Stefano Zampaletta explains, “The true measure of D-Carb’s impact lies in its adoption by customers and the tangible benefits in real projects. Feedback from early adopters has been overwhelmingly positive, emphasising the product’s ease of integration, performance consistency, and contribution to decarbonisation goals.”

Across all regions, customers have highlighted several key product benefits:

• smooth transition – Industrial users consistently report that D-Carb integrates seamlessly into existing production processes, requiring minimal adjustments and enabling a swift shift towards lower-carbon products.

• performance assurance – The product delivers high early strength, excellent workability and consistent whiteness, meeting the stringent requirements of both precast and architectural applications.

• sustainability leadership – By adopting D-Carb, customers are able to reduce the carbon footprint of their products, align with evolving regulatory requirements and enhance their competitiveness in public tenders and private projects alike.

Nevertheless, it is crucial to share testimonials of user experience in using D-Carb.

For example, extensive testing, C-concrete adopted D-Carb for two flagship projects: the 380 kV GIS highvoltage substation in Amaliahaven, The Netherlands, and the AZ Jan Portaels Hospital in Vilvoorde, Belgium. In these demanding precast applications, D-Carb delivered the required strength, high whiteness and workability, enabling innovative architectural designs and supporting the clients’ sustainability objectives. The transition required no major changes to mix designs, and the product’s performance was described as “reliable” and “outstanding.”

Enjoy Concrete, another early adopter, used D-Carb® in the Aquamarijn Residence project, a striking 11-storey coastal development in Belgium. The company reported a fluent transition from Aalborg White CEM I, achieving comparable early and 28-day strength and excellent workability, combined with reduction in emissions. The project’s success demonstrates how D-Carb enables highquality, sustainable construction without sacrificing technical or aesthetic standards.

Enjoy Concrete successfully used Cementir Group’s D-Carb® white cement in the Aquamarijn Residence project in De Panne, Belgium

Conclusion

The D-Carb range represents a significant step forward in the decarbonisation of white cement, combining technical innovation, industrial validation and customer-centric deployment. Through rigorous initial testing, a strategic global roll-out and strong customer partnerships, Cementir Group is helping to drive the construction industry towards a more sustainable future where lower carbon emissions, high performance and architectural excellence go hand in hand.

Attachments

Pioneering sustainable transition in white cement | ICR January 2026

Share on