China Xuan Paper Town, with a construction area of 10,695 square meters, is a charming little town located in Jing County, Xuancheng City, Anhui Province. Designed by China Academy of Art and constructed by Xuancheng Municipal Construction Group, the town is centered around the China Red Star Xuan Paper Plant, which is the heart of the town. What makes this town unique is that it serves many functions such as production, exhibition, sales, accommodation, research, tourism, and much more, all of which are centered around the Xuan paper culture. The town aims to become a significant hub for Chinese Xuan paper culture in the future.

A Journey Through the Seamless Integration of Architecture and Landscape

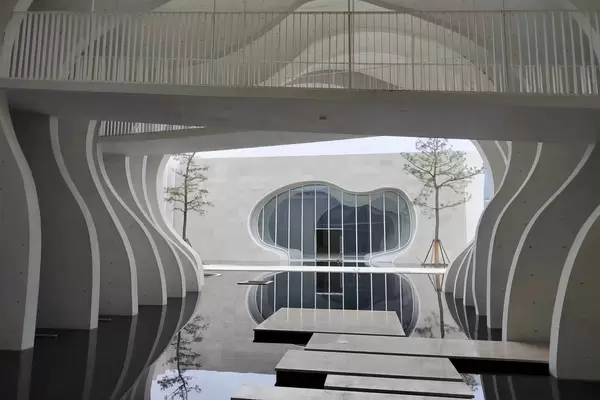

The architecture and landscape on the banks of the Wuxi River are seamlessly integrated in architecture design, with white concrete shaped as giant paper sheets serving as the primary element. This creates a picturesque "paper mountain" landscape that conveys the unique charm of Red Star Xuan Paper. Walking through the mountain feels like stepping into a painting.

The design elements include the architectural expression of Xuan paper texture, large areas of white space, minimal objects to control the picture, and the creation of a spatial artistic conception. The multiple paths and continuous slope design enhance the unique charm of the Paper Mountain journey, allowing visitors to enjoy a pure and spectacular touring experience as they navigate through the separation of white concrete sheets.

The construction is situated by the water and surrounded by mountains, it is enveloped in a mystical mist that adds to its ethereal feeling. The way in which it seamlessly blends into its natural surroundings is truly remarkable. The building's design incorporates elements of Chinese ink painting, creating an immersive experience for visitors. On a sunny day, the reflection of the building in the water is simply stunning. The architect's use of closely ordered sheet wall design, combined with the reflection of sunlight on the concrete surface, creates an ever-changing interplay of light and shadow that makes the building come alive.

The rustic concrete surface is utilized to express the unique texture of handmade Xuan paper, which is a testament to the skill and dedication of craftsmen. The concrete's beauty and durability are used to express the charm of Xuan paper, which is known for its ever-changing ink charm and a lifespan of a thousand years. The use of white concrete materials perfectly represents the white and non-fading features of Xuan paper.

The scenic area features four distinct areas, each with its unique theme. The first area, "One Cave," is designed to invite visitors into a painting, with a carefully crafted mountain cave that leads to a series of interlocking paper "caves." The second area, "One Sheet of Paper," showcases the paper-making process with a large, curved slope that integrates different stages of production into an open space. The third area, "One Field," combines the unique terraced landscape of Huizhou with the traditional handmade paper-making techniques to create an experiential area where visitors can observe and participate in the process. Finally, the "One Hall" area is dedicated to the sale of Xuan paper, the famous handmade paper from Anhui province. Together, these four areas offer a comprehensive and immersive experience of the rich cultural heritage of the region.

Project Features

The project features a complex design with numerous changes in plan, elevation, and space to optimize land use while preserving the original topography. Three interconnected buildings make up almost 11,000 square meters of construction, primarily consisting of huge frames of thin shear walls and large-span thin concrete beams forming the roof all cast-in-situ. The project won the "Da Vinci" Gold Award at the Florence Art Biennale in Italy.

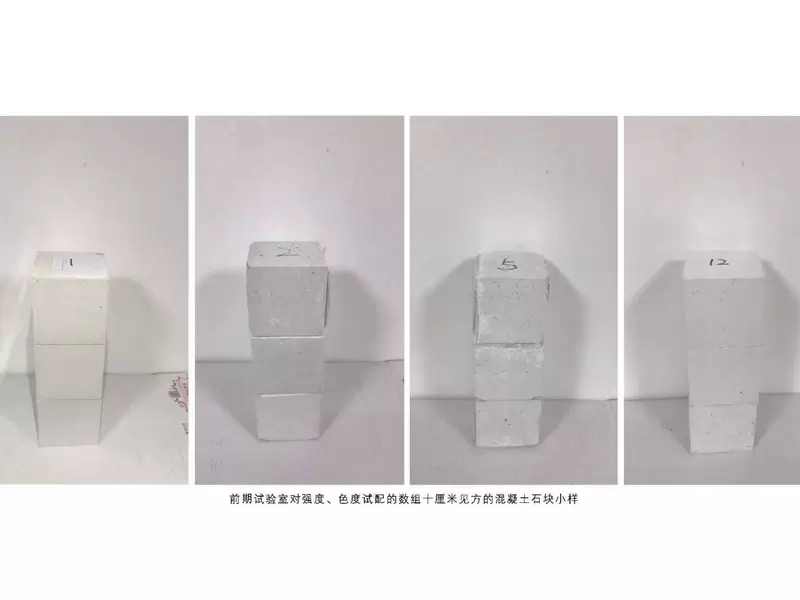

The roof structure has a maximum net span of 36m, exceeding normesign standards, and forms a continuous curved surface with no two identical concrete beams. The main structure is made of white fair-faced in-situ cast concrete, with approximately 70,000m2 of exposed concrete surface, which requires strict material storage, production, and transportation standards. Concrete dimensions were required of high precision, with allowable tolerances of only 3mm for verticality, 2mm for flatness, and 2mm for formwork joints.

White cast-in-place concrete

This modern architecture employs cast-in-place concrete technology using white concrete based on Aalborg White cement - also known as decorative concrete.

This technology involves onsite pouring of freshly mixed concrete into formwork creating the final shape. The formwork is stripped after a few days and the concrete structure is essentially ready. Simple but complex. A one-time pouring and forming process, resulting in a smooth white decorative surface. The texture of the surface mimics the formwork surface with its joints and clamp holes, forming a surface that showcases the essential beauty of concrete. White fair-faced concrete is considered one of the most advanced and honest expressions of the concrete material, with a tactile appearance, providing a simple and natural sense of robustness and elegance that cannot be replicated by other modern building materials. The truthful surface of white fair-faced concrete discloses the nature of concrete with smooth areas of white shades, holding the characteristic marks from clamp-holes and joints from formwork.

Complex Construction Process with Several innovations

The project requires a unique formwork assembly system due to its complex structure. The construction team has come up with innovative ways to prevent any leaks or unevenness in formwork joints. They are using high-quality materials such as surface impregnated formwork plates, strong square wood to stiffen the formwork, steel pipes as back ribs, and patented bolts and plugs. special white mortar spacer is developed to ensure that the reinforcement steel is fixed correctly inside the formwork and at the same time do not discolor the white concrete surface.

To avoid exposure and corrosion of the reinforcing steel bars, they're positioning the reinforcement accurately and facing the twisted wire knots inward. After the formwork is removed from the concrete, the team is taking extra care to protect the surface from damage or contamination, which secures the quality of the concrete and reduces the need for rework.

BIM technology is a key focus in project management, using 5D technology to identify errors and optimize construction processes. Diagrams are created for all formwork and clamp holes for plain concrete, ensuring construction progress is orderly and avoiding rework.

The large-span thin beam structures are monitored and controlled in real-time in order to ensure safety. This by monitoring concrete deformation. 12 monitoring points have been set up at selected locations and are monitored 24/7 for 6 months.

The Spirit of Craftmanship

The construction of the "Paper Mountain" project was extremely challenging due to its intricate structure and numerous restrictions on scale, visual appearance, and style. This type of building has a rich heritage that creates tension in cultural time and space, which is not just different or metaphysical, but a naturally generated logic.

Therefore, the construction team did not overlook the building's natural essence during construction, nor did they intentionally pursue material application techniques. Instead, they persisted in adhering to the building itself. This persistence embodies a spirit of craftsmanship that is ingrained in their blood and bones, with an unwavering focus on quality and a heart of reverence.

After three years of meticulous work, the collaboration of designers, construction teams, owners, and material suppliers successfully achieved the design intent of "stacking rolls into mountains, hanging curtains like smoke, and a floating platform like water," resulting in a feasible, desirable, and picturesque white concrete "Paper Mountain."

Project credits:

Project Owner: China Xuan Paper Town Co., LTD

Contractor: Xuancheng Municipal Construction Group Co., LTD

Architecture Design: Landscape Architecture Design and Research Institute of China Academy of Art Co., LTD

White cement supplier: Aalborg Portland Anqing (Cementir Group)

Share on