Introduction

When Hans Henrik Bache invented and further developed his highly modified cement paste known as Densified Systems containing homogenously arranged ultra-fine Particles (DSP) in 1978, it was often mentioned in literature with the classification Very High Strength Concrete. Like in traditional concrete strength was, and still is, the most important characteristic or performance to describe and specify. In traditional concrete technology, compressive strength is the most important mechanical property and is often related to other mechanical properties and durability.

According to Professor Pierre-Claude Aïtcin’ Professors Roger Lacroix and Yves Malier introduced the expression “High Performance Concrete” around 1980. However, other sources are mentioning that Dr. François de Larrand used the name “High Performance Concrete” for the first time in his publications. An important remark from Professor Piere-Claude Aïtcin in his book “High Performance Concrete”: “There is no doubt that this new type of concrete offers more than just a high compressive strength. In spite of the fact that up to now (first publication 1998) High Performance Concrete has been used primarily in high strength applications , it is inevitable that in the very near future high performance concrete will be mostly specified and used for its durability rather than specifically for its high compressive strength” and “In the present state of the art, it is not possible to make a durable High Performance Concrete that does not have a high compressive strength, but this situation can evolve.”

The P is for Performance!

Performance is the action or process of performing a task or function. Thus, for concrete: the concrete specified, or the concrete product made must fulfill the task or function it was designed for. I do believe that in modern construction basically, every material must perform according to the demands and/or standards.

What is high performance for concrete: the concrete specified, or the concrete product made must fulfill the task or function it was designed for according a high standard. Thus, not that it must perform better and/or be stronger.

Later Ultra High Performance Concrete (UHPC) was introduced for concrete with much higher compressive strengths. But what about their performance?

What is ultra high performance for concrete: the concrete specified, or the concrete product made must fulfill the task or function it was designed for according an ultra high standard. Thus, not that it must perform much better and/or be much stronger.

Ultra thin Hybrid Reinforced Ultra High Performance Concrete overlay on insulation cold store auction hall

Thus, to perform, high perform or ultra perform will depend on the specific task and/or function the concrete or the concrete product must fulfill. Performance is not always, certainly in practical applications of UHPC, related to the compressive strength of the concrete used. I have used since 1985 more than 50 types and mixes of UHPC in the business areas: Security Industry, Wear Protection, Offshore and Civil Engineering and learned that performance for specific applications are often more depending on other properties than the compressive strength.

The ultra high performance is often not at all related to compressive strength. UHPC used for wear protection in the processing industry handling large quantities of abrasive materials in their production plants is showing that there is often no relation between the high level of wear resistance and the compressive strength. We learned from Hans Henrik Bache’s theories and the many tests with Compact Reinforced Composite (CRC) that the compressive -, flexural - and shear strength of an UHPC composite are not depending on the compressive strength of the UHPC used in combination with hybrid reinforcement.

Compressive strength or Performance?

Today, with standards and guidelines for UHPC in several countries around the globe, UHPC is still too often classified as a concrete with a compressive strength of >150 MPa or, depending on the standard or guideline, >120 MPa and a tensile strength greater than 5 MPa. When the strength is the most important mechanical property, we should perhaps use the classification Ultra High Strength Concrete.

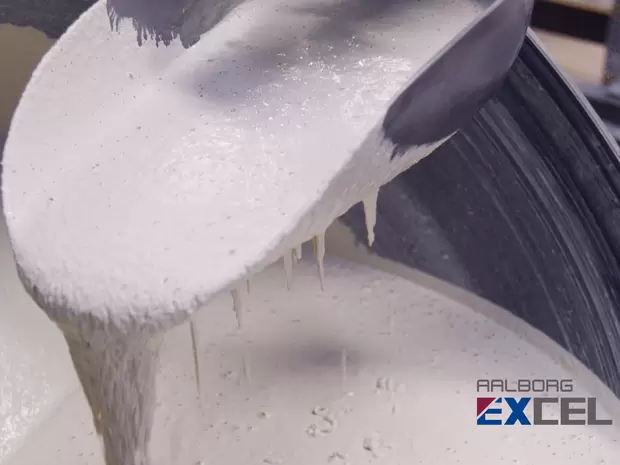

Pouring of large vault door with Ultra High Performance Concrete

In general, people assume that any concrete with a compressive strength above 150 MPa is an UHPC and that all UHPC’s have the same ultra high performance (properties wet and cured concrete). However, even when the same compressive strength is reached there can be large differences between the properties of the UHPC products and/or their suppliers. This is extremely confusing since many still believe that it is all the same grey stuff (sometimes white but that is even more complicated). Also, in project tenders confusing or even wrong descriptions are used. For example, in the tender description for the façade panels of an embassy 3 acceptable manufacturers and products were described but no properties were mentioned. As a basis of design manufacturer, they use two products of a well-known supplier, however, both products have a compressive strength in the range of 110 – 130 MPa while the other two suppliers had different properties of their material. On another page they refer to another product, thus product 3, of the same supplier with properties which were completely different, this was clearly UHPC, and including metallic fibers. Further, they demanded, related to potential bomb attacks, a limiting deflection so the windows behind cannot be impinged and that the UHPC panels stay intact rather than breaking into pieces significant enough in size to become hazardous projectiles. UHPC can be used extremely well to resist high impact and even ultra-high impact of explosives as already demonstrated by Bache with CRC panels, but this demands other performance and another fixation of the panels than described in the tender documents.

Very slender precast Hybrid Reinforced Ultra High Performance Concrete bridge panels

Ultra thin Hybrid Reinforced Ultra High Performance Concrete overlay on concrete viaduct

It is thus too often the case that there is some misunderstanding and confusion and that the UHPC specified or the UHPC product made, cannot fulfill the task, or function it was designed for according the high – or ultra high standards. Unfortunately, there are some recent examples of this misunderstanding between supplier and client and/or not delivering according to the standards on large projects. Or, what as often happened, that the UHPC supplied is performing too well and thus actually too expensive and unnecessary for the specific application.

My thoughts about UHPC: Performance is the key factor!

A concrete, with whatever classification, should perform according to the properties needed for a specific project. The properties of the wet and cured concrete will depend on the specific project and specific circumstances. When it performs better, compared to traditional concrete, it is high performance and when it performs much better it is an ultra high performance. But a better performance will cost, in many ways, more and is not always needed. That’s also the reason that most of the UHPC’s are, in fact, a HPC with an ultra high performance for that specific application.

Strengthening orthotropic steel deck with bonded Hybrid Reinforced Ultra High Performance Concrete

(credit Beeldbank Rijkswaterstaat)

We should focus less on the compressive strength, fancy names, and abbreviations of this “modern” concrete, but we must start to specify HPC and UHPC much better based on more uniform tests and proven performance for a specific project. Thus, a tailor-made concrete performing excellent according to demands and specifications while taking impact on environment and resource consumption in account. That should be our goal!

Share on