Hyllie Terrass is an office building in Malmö, Sweden, developed by SKANSKA, with precast and steel structures produced by UPB Group. This white concrete building stands out not only for its high aesthetic appeal but also for its commitment to being first climate neutral office building in Sweden. This remarkable structure combines sustainability with stunning design elements, creating a harmonious blend of beauty and environmental consciousness.

Project credits:

Developer: SKANSKA

White Precast Concrete: UPB Group

Architecture Design: Cobe Arkitekter

White cement: Aalborg White

Area: 14 000 m2

Floors: 12

Sustainability in Every Aspect

This 12-story office complex is Skanska's first-ever carbon-neutral building, and it's part of a pilot study conducted by the Sweden Green Building Council for NollCO2 certification.

NollCO2 certification ensures no additional CO2 emissions throughout the building's lifetime. It covers everything from design to operations, including manufacturing, transportation, recycling, and energy solutions. Strict emission targets must be met to obtain this certification. UPB worked closely with SKANSKA from the beginning of the project to reduce CO2 emissions, especially in concrete and steel structures.

UPB experts provided different strategies for design, manufacturing, and logistics, resulting in significant reductions in CO2: around 33% for prefab elements and 53% for steel elements. These results were compared to UPB's environmental product declarations from 2015. In addition to NollCO2 certification, Hyllie Terrass will also be certified for sustainability (LEED) and health (WELL).

Hyllie Terrass serves as an inspiration for future office buildings, showcasing that sustainability and aesthetics can go hand in hand. By prioritizing climate neutrality and incorporating high visual appeals, this remarkable structure proves that it is possible to create beautiful spaces while minimizing environmental impact.

Signature Look with the White Precast Concrete Façade

To achieve a bright white surface for the façade, a unique recipe was developed. Aalborg White Portland cement, Titanium Dioxide (TiO2) pigment, and white silica fume were used as additives. High purity and chemical stability of the white cement plays a paramount importance for producing high-quality façade surface. When mixed with pigment and additives, it ensures consistent concrete properties and appearance. TiO2 is a highly refractive and UV-resistant material that significantly increases the brightness of the concrete. White silica fume improves both the fresh and hardened states of the concrete. In the fresh state, the ultrafine and spherical particles of silica fume increase the concrete paste volume, making it more stable and flowable. In the hardened state, silica fume acts as an effective pozzolanic material that reacts with the free calcium hydroxide in the concrete. Silica fume reduces permeability, increases durability, and allows for lower cement content while maintaining concrete strength.

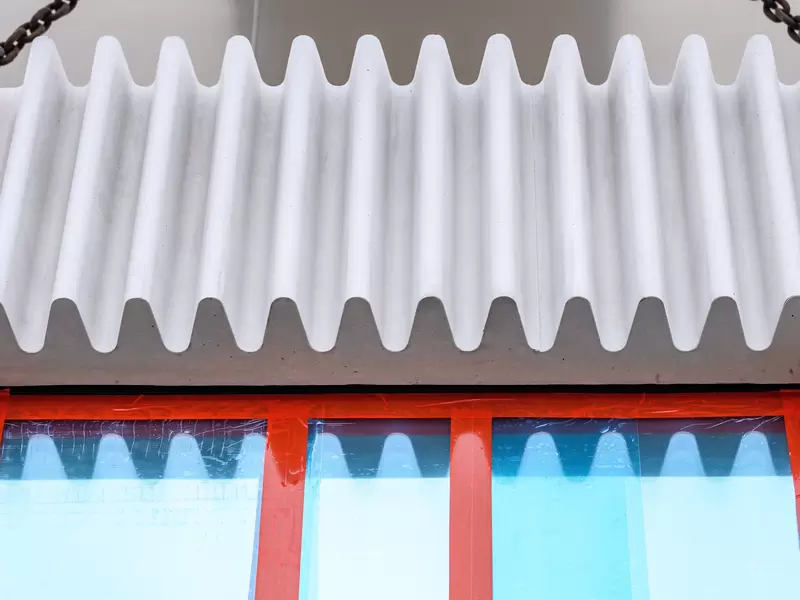

The façade was designed using a Design for Manufacturing and Assembly (DfMA) approach, which ensured that only three types of modules were used. These modules consisted of flat vertical and horizontal grids, one window, exterior sills, and a recessed ribbed pattern that is 125mm deep.

The building's overall visual character is enhanced by the interplay of light and shadow. The white façade stands out in contrast to the green facades on upper floors, creating a striking effect.

Off-site construction

Before delivery, large aluminium frame windows were pre-installed in concrete facade elements at the factory. Each floor assembled on the construction site creates a sealed building space. The façade is ready, and the internal walls are prepared for final finish.

Share on